Available on the SC-16

Available on the SC-16

Available on the SC-15 and SC-16

Available on the SC-15 and SC-16

Available on the SC-16

Available on the SC-16

Available on the SC-16

Available on the SC-16

Firewood Processor Features

New Splitter Autocycle

With the new Rapid Split SC16, you can produce up to 6 full cord an hour. Featuring a splitter autocycle with a under 4 second full cycle time with hi-lo two speed. One button splitter operation with adjustable stroke length to save even more time.

New Murphy Panel

The new 2024 SC16 panel is equipped with a new Murphy PV-485 4.3” LCD engine control, along with emergency stop on the panel

Updated Trough Chain

The redesign of our trough cleats improves log feeding

Standard Wedge Holders

The 2024 SC16 Rapid Split features two standard vertical wedge holders for easy accessibility

Easier KDI Service

We have rotated the engine 180 degrees for easier service and accessibility

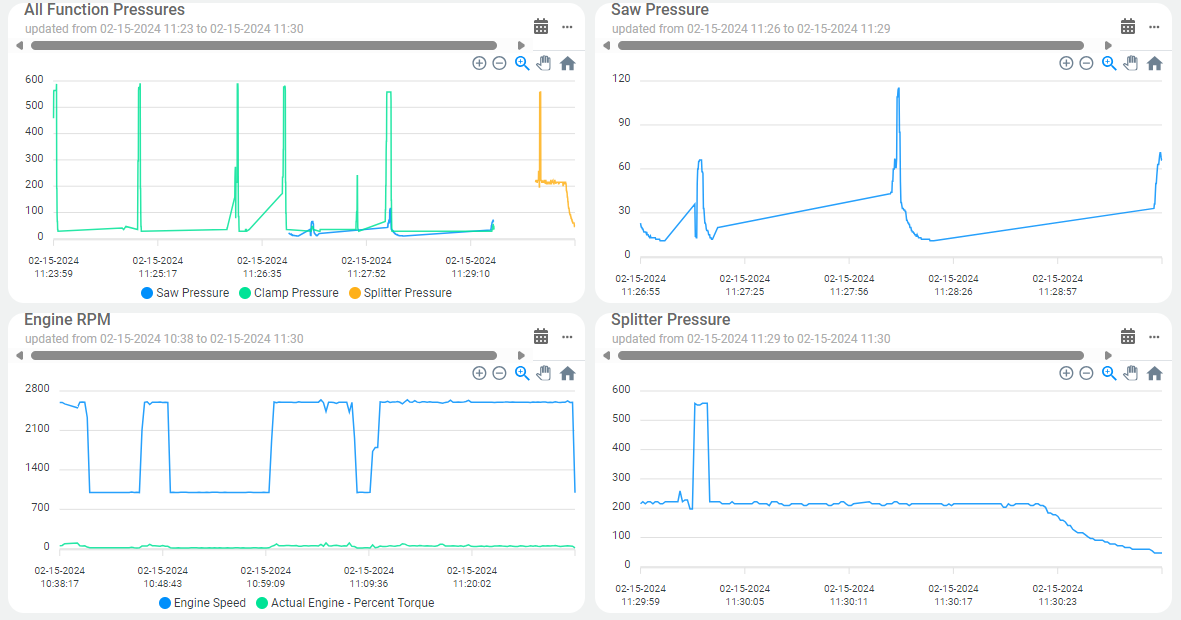

MyDyna Portal

Through the MyDyna portal you have data from the hydraulics to the engine, along with being able to track your processor’s location when it is running. You also have the option to disable the machine if it is lost or stolen while out on rental

Updated Log Deck

The improved log deck spacing is designed for 4’ logs on two deck arms and 8’ on three deck arms

2024 New Safety

Safety interlocks prevent the plunger from operating when the doors are open

Positive Stop

Get constant cut lengths with our positive stop. Its built with 3/8th” steel plate and 2.5″ square tubing. With the removal of one pin you are able to adjust the length of your cut pieces by 1″ increments.

Operator Station

Stainless steel dash includes 2 cup holders and USB cell phone charge port and tool tray.

Sawdust Bagger

Need additional help with Bagging the saw dust? Our new sawdust bagging can help with those issues.

In 2021 we added a three-year warranty, aggressive in feed trough cleats, High-Performance DYNA Saw Bar, and a new oiler control

Aggressive in feed trough cleat

Need additional help with crooked logs? Our new aggressive feed can help with those issues.

Heavy Duty Tread Plate Fender

Do you have fenders on equipment that is bent up? Not with our new heavy duty tread plated fenders that are new on our 2021 models

High Performance DYNA Saw Bar

We have now designed our own saw bar for better performance and longer life span. This bar features a more broad body and nose for more stability and support.

Oiler Control

.jpg)

No need to run around the machine to adjust our bar oiler. Its now on the operators station for the ease of our operator.

2020 Rolling Clamp

Feeding crooked firewood logs can be a challenge, and how many firewood logs are straight? The DYNA log clamp was designed to securely and conveniently hold the log in place for cutting, especially the last cut, without any complicated log trays or fussy hydraulics. It does that, plus helps feed crooked logs by pushing the log into the infeed cleats. At DYNA, we know cycle time isn’t the only feature that increases production. The rest of the machine needs to

be built right as well

Conveyor

Do you ever wonder if we are truly working for our customers? The 2020 DYNA conveyor shows how much we care about your comfort and convenience. DYNA engineers spent many months prototyping our new conveyor to achieve flawless performance. No more wrestling with unwieldy conveyor wheels that get stuck in the ground, no more pushing on the conveyor for setup. With the simple push of a button, the conveyor on your DYNA will stretch out in one piece with no further effort from you. Setting up to cut wood has never been safer, more comfortable, or more convenient. Faster too because we know you’ve got lots to do. The 2020 conveyor is 2 feet long as well. At 16 feet long, you will be loading your tri-axle with ease or making giant piles for your neighbors to marvel. Check out our video and see for yourself!

Bolted hitch jack attachment

.jpg)

What is more important, the present or the future? DYNA likes to prepare for both. The hitch jack on your DYNA is now bolted fast instead of welded. We know you will always be careful, but not everyone is, and now if that daydreamer neighbor bends the jack on your DYNA, a new one can take its place with only minutes of wrenching.

Wedge Hold Down System

You asked, and we listened! Our 2020 wedge features a hydraulic cylinder attached to the wedge for power up and down! Our updated 6-way wedge also features highly engineered angles to increase splitting performance and reduce stress on other components. Our engineering team went back to the drawing board no less than 12 times before they were satisfied. There is even more, in any case. Our wedge also features an integrated handle that makes changing your wedge a breeze! Don’t forget about our wedge holder that comes with every SC-14, SC-15, and SC-16. Never worry about the safety of your second wedge; it will be right where you secured it on your DYNA.

Log Flipper

.jpg)

The new DYNA log flipper assists in getting crooked logs from the live deck to the log trough. Strong and aggressive, the steel fingers will push against the log—no more logs slipping on the chains and production delays. Crooked logs stand no chance against the DYNA. Standard feature on most 2020 models

Upgraded wedges

.jpg)

In 2020 we have been focusing on the small details. One of the features was our wedge. We improved the strength also added a handle that makes it easier to install and remove the wedge. We also started marking our wedges with a serial number and what generation just like airplane parts! We also improved the design of our 2020 splitting wedges

Log Trough Angled Downward

.jpg)

Do little things add up to big things? We think so, the ends of your DYNA log trough are now angled downward to increase the ease of feeding those long crooked logs we all love to cut!

Engine Control

LCD engine control displays hydraulic system pressures and oil temperature readings in real time

Chain Guide / Wood Guard

.jpg)

Deck chain guides have been added for consistent alignment when lowering the live deck and helps prevent wood from getting stuck

Sawdust Chute is standard on SC-15 and SC-16

Sawdust chute is now standard which keeps your machine cleaner and controls the sawdust for easier removal.

Upgraded Bar and Chain Oiler

.jpg)

The bar oiler has a longer stroke and a larger infeed line for better performance in extremely low temperatures.

Standard Hydraulic Deck Lifter

The hydraulic deck lift is now standard on the SC15 and SC16. We use heavy wall seamless pipe and split collars for an extremely tight, rigid deck

Heavier Gauge Shields

All shields are made from thicker material than ever before. The guards around the splitter chamber are 1/4 inch plate.

Hydraulic Deck Lift Pipes, Bushings, and Split Collar

.jpg)

The hydraulic decklift is now standard on the SC15 and SC16. We use replaceable bushings in pivot points to increase life.

2-5/16 inch Hitch with lights, and Trailer brakes

SC14, SC15 and SC16 have 2 5/16” adjustable ball hitches with lights and trailer brakes

Quality Control Checks

Assembly checks all fasteners and marks them as tight. QC checks everything again and marks each bolt with a marker. All company quality standards are at an all-time high. We incorporated Zero Defects from the automotive industry which yields a much higher quality product

Log Measuring Scale

The trough has a log measuring scale which indicates how much log is remaining on the deck.

Saw Motor Assembly

The saw motor assembly is protected by the new splitter guard to prevent wood pieces from damaging it.

Winch cable Routing

The wiring for the winch has been rerouted for better appearance and is less prone to damage.

Hitch Pins and Steel Lanyards

.jpg)

All hitch pins have steel lanyards to keep the pins and keepers from becoming lost.

Conveyor Pin

No more pin to remove when setting up the conveyor! The new design hangs from two short cables and doesn’t need to be touched.

Deck Arm Rubber Bumpers

.jpg)

The deck arm stops have rubber bumpers for less shock and harmful impact when folding up the deck.

Upgraded Painting Process

.jpg)

We DA sand or sandblast all surfaces before painting for maximum paint adhesion. We also do our painting in house with a state of the art paint and sandblast booth.

Upgraded Saw Shaft

.jpg)

The saw shaft is now 1.5 inch in diameter and pressed into a machined steel block.

Rerouted Hydraulic Hoses

Hydraulic hoses have been rerouted for a cleaner look and easier maintenance.

.JPG)

.jpg)